robot guarding impact testing|osha robot safety standards : services Impact testing – the fence had to be thoroughly impact tested at any point where a robot might breach the perimeter guarding. NPSG set up testing areas in its Kennesaw and Reno warehouses. Portions of the guarding and guarding components were tested to verify the guarding was within tolerances. Impact testing needed to be digitally captured . WEBAgora temos algo para todos os amantes de Free Fire! Podemos finalmente obter contas traídas e veteranas de Free Fire em questão de minutos graças a gerador de conta .

{plog:ftitle_list}

გაიგე მეტი - Crystalbet

A revision of ANSI R15.06-1999, this standard provides guidelines for the manufacture and integration of Industrial Robots and Robot Systems .When building machine guarding, consider material selection, impact resistance, stiffness, lightweight, optical clarity, and chemical resistance. Commonly used - Polycarbonate, acrylic, PETG, and clear PVC. . In the .

Satech’s OSHA approved Machine Guard BASIC Series is a competitive and extremely versatile Solution when you need to perimeter your machinery with an ANSI machine guarding.It features two different fixing options: the Captive . The first video shows a short length of Satech Basic series guarding being subjected to impact testing, with a load of 100kg being swung so as to strike just above the middle of a panel that is supported on either side .

Impact testing – the fence had to be thoroughly impact tested at any point where a robot might breach the perimeter guarding. NPSG set up testing areas in its Kennesaw and Reno warehouses. Portions of the guarding and guarding components were tested to verify the guarding was within tolerances. Impact testing needed to be digitally captured .with you opera ng the machine safeguards and others in the work 1. An employee trained on his you can take it off as long as you area are protected also, you are . primary machine can fill in as. replace it at the end of the shi L. good to operate your machine. the operator of another machine T or F T or F. because he knows his machine’s 3.Two new informative annexes on test methods, one on projectile tests and the other on impact tests, have been added. The Bibliography, which contains a list of International and European Standards published or in preparation that can be helpful in the design and commissioning of guards, has been updated.80/20 Minimize risk - Keep your people, equipment, and property safe with 80/20 T-slot machine guards, create physical barriers, security frames, and more. The store will not work correctly in the case when cookies are disabled. . custom guarding and enclosures aid in damage protection and loss prevention. Physical and visual partitions set .

Moving machine parts have the potential to cause severe workplace injuries, such as crushed fingers or hands, amputations, burns, or blindness. Safeguards are essential for protecting workers from these preventable injuries. Any machine part, function, or process that may cause injury must be safeguarded.

Discover our cutting-edge impact protection solutions. Our tested blast shields, Kevlar blankets, explosion containment enclosures, shielding rooms, and modular barriers ensure the safety of your personnel and equipment. . Machine fitting enclosures that enable observance of machine operations for closer perimeter guarding. See Product.

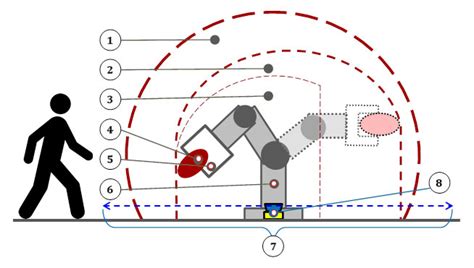

Welcome to our YouTube channel where we bring you the latest and greatest in industrial safety solutions! Today we are excited to showcase the Troax Machine .These guarding systems are of low carbon steel construction. Upright posts and panel frame members are extruded tubes for extra durability. The construction methods utilized make the assembled system impact resistant up to1600J in ISO 14120 dynamic resistance tests – exceeding the standard set by many automotive manufacturers.Impact, Collision, or other "Struck-by/Caught-between" Hazards . It is typically during the assembly, installation, and testing of the robot applications where many of the above listed hazards are introduced. The following hazards must be considered: . 29 CFR 1910 Subpart O - Machinery and Machine Guarding 29 CFR 1910.211, Definitions.Instron manufactures tensile, compression, fatigue, impact, rheology, and structural testing machines, testing a variety of materials and range of applications. Telephone: +1 800 877 6674

Machinery and Machine Guarding: 29 CFR Part 1910, Subpart O • 1910.211 – Definitions • 1910.212 – General requirements for all machines • 1910.213 – Woodworking machinery require-ments • 1910.215 – Abrasive wheel machinery • 1910.216 – Mills and calenders in the rubberAll hardware comes secured to the bracket and will not disengage upon impact. 07. 4″ Sweep Space. 4″ sweep space for easy cleaning access. 08. Fortress Interlocks. . Machine guarding is necessary for any business that utilizes .On often overlooked area of guarding selection is impact testing. Guarding should both ensure an operator cannot enter the safeguarding space from the outside until it is safe to do so and protect operators stood outside the guard from projectiles and emissions from within.The Troax Test Centre is the heart of our business. Here, our products . machine guarding system with new mesh panels, doors and locks. ISO 12100 ISO 14120 ISO 14119 ISO 10218-2 . Our strongest machine guard that can withstand an impact of 2,500 joules. 1 RAPID FIX

Identifying potential hazards is the first step toward establishing effective machine guarding practices. Common machinery hazards include: Pinch points: Areas where two rotating parts meet or move together and could trap a worker's body part. Rotating parts: Shafts, gears, belts, and other parts that spin and can cause entanglement or severe injury.Impact-Resistant Assembly. Our latest ImpactGuard captive fastening system complies with the Machinery Directive (2006/42/EC) and offers a streamlined design with fewer components, significantly improving assembly efficiency. This System also ensures superior impact resistance, meeting the rigorous standards of the Impact Test as per EN ISO 14120. Machine guarding plays an important role in keeping workers safe. According to the U.S. Occupational Safety and Health Administration (OSHA), roughly 18,000 workers are injured per year due to unguarded machinery. OSHA, however, requires the use of machine guarding. It's an essential safety measure that minimizes the risk of machine-related .

One or more methods of machine guarding shall be provided to protect the operator and other employees in the machine area from hazards such as those created by point of operation, ingoing nip points, rotating parts, flying chips and sparks. Examples of guarding methods are—barrier guards, two-hand tripping devices, electronic safety devices, etc.safe machine guarding for your personnel and machine safety in accordance with ISO . test center. The panels are tested using energies of up to 2,500 joules, which is a very respectable level . 18 5.4.2 Impact and ejection resistance 18 5.4.3 Rigidity 18 5.4.4 Secure fixing To underscore the positive impact of effective machine guarding, business owners can look to relevant case studies. While specific case studies may vary, showcasing successful implementations from reputable companies or industries highlights the tangible benefits of prioritizing safety through advanced machine guarding solutions.

One call to Machine Safety Specialists (MSS) can solve your OSHA machine guarding, risk assessment, functional safety and safety training needs. Since 1977, MSS has helped businesses improve industrial workplace safety and become compliant with OSHA, ANSI, NFPA, RIA, and ISO/EN machine safety standards. Safeguarding standards. OSHA doesn't have a specific standard on industrial robots. OSHA's general view on robot safety is that if the employer is meeting the requirements of ANSI/RIA R15.06, Industrial Robots and Robot Systems-Safety Requirements, then the manufacturer has no issues.

osha robot safety standards

osha robot exposure to fire

How Charpy impact tests are performed. Specimen Preparation: A small, standardized specimen, usually a rectangular bar with a V-shaped notch machined on one side.The notch creates a stress concentration that promotes fracture when impacted. The test setup includes a pendulum hammer, a notched specimen holder, and a digital or analog .

Machine guarding refers to protections on or around machines to safeguard human operators from hazardous conditions or injury. Machine guards, sometimes referred to as safeguards, are the protective devices that cover the hazardous or injurious parts of engineering machines. According to OSHA, poor machine guarding leads to about “18,000 .

impact testing for machine guarding

Faça parte da comunidade vencedora do Deusa777! Cadastre-se agora e experimente a emoção dos jogos de azar online no coração do Brasil. Nosso login fácil e seguro abre .

robot guarding impact testing|osha robot safety standards